Quality Policy

In alignment with national standards and legal regulations in Mongolia, we implement cutting-edge technology and continuous improvement throughout all stages of mining and steel production. By utilizing results from accredited laboratories, we ensure the delivery of high-quality products that meet customer expectations and requirements, ensuring their satisfaction.

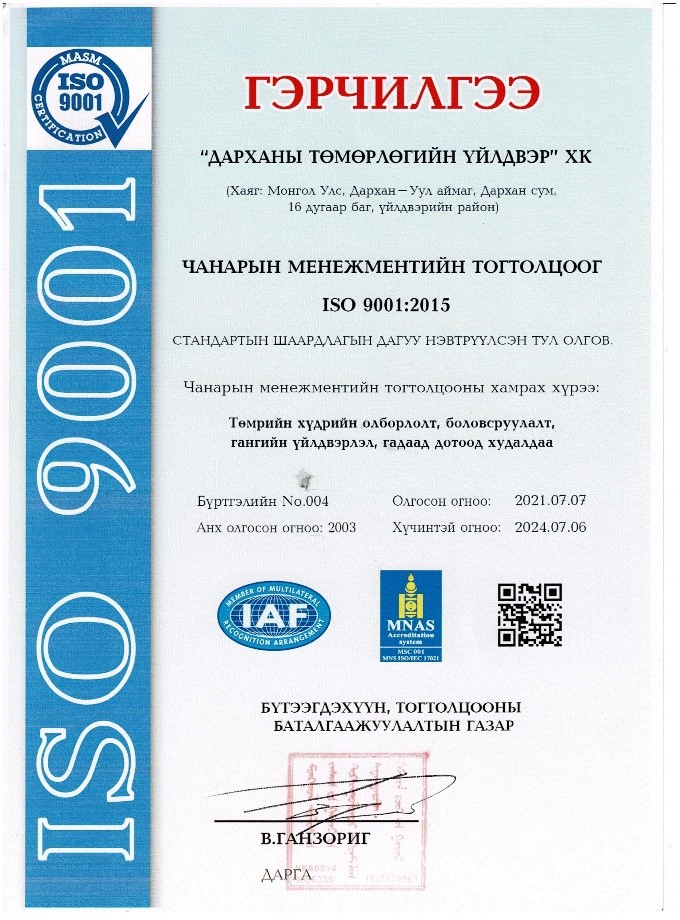

Quality Management

Our Quality Management System (QMS) is fully compliant with the MNS ISO 9001:2016 standard. This system is thoroughly documented and ensures that all technical and technological processes meet customer and regulatory standards. We maintain a system of regular monitoring and continuous improvement to meet the evolving needs of the industry and our clients.

Quality Control

We ensure quality across every phase of production, from raw material selection through to final products. Our quality control includes verifying the composition and characteristics of raw materials, monitoring the entire production process—such as ore quality, concentrate production, and billet manufacturing—ensuring that every product, including steel and rolled materials, adheres to the required standards. In cases of non-conformity, corrective measures are swiftly implemented to ensure products meet specifications at every stage.

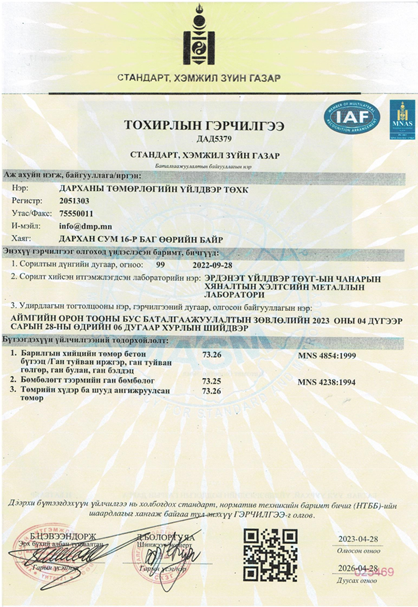

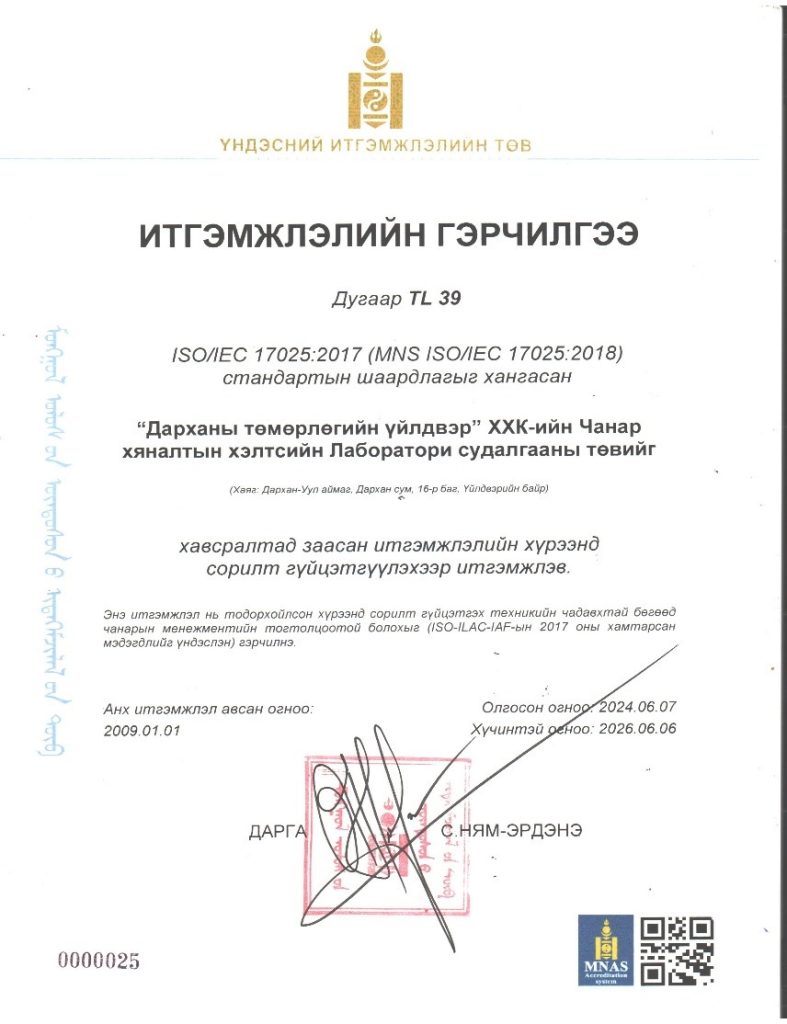

Laboratory Operations

Our laboratory operates under a quality management system compliant with the MNS ISO/IEC 17025:2018 standard. We perform testing on a wide range of materials, including iron ore, concentrates, alloys, fire-resistant materials, steel, cast iron, and non-ferrous metals. Our lab equipment is state-of-the-art, allowing us to evaluate chemical composition, hardness, and mechanical properties in accordance with Mongolian standards. The laboratory has been accredited by the National Accreditation Center of Mongolia and the Standardization and Metrology Agency in 1999, 2002, 2005, 2009, 2013, 2018, and 2024.

Quality Control Department Activities:

Mining Operations:

- Drilling and Sampling: Implement robust quality control measures during drilling,

sampling, and the creation of ore stockpiles, ensuring adherence to ore reserve

specifications and operational requirements. - Ore Processing and Metallurgical Recovery: Conduct thorough quality checks on ore

processing, metal recovery, balance calculations, sample collection, and the distribution of concentrate stockpiles. - Sales Samples: Oversee quality control for both export and domestic sales samples,

ensuring all products meet quality standards based on laboratory analysis results.

Steel Plant Operations:

- Scrap Metal Quality Control: Perform detailed quality inspections on incoming scrap metal to verify compliance with required specifications.

- Scrap Metal Supply: Implement continuous quality control throughout the entire scrap

metal supply chain to ensure consistent product quality. - Billet Production Quality: Monitor and enforce quality control standards during billet manufacturing to ensure conformity with production specifications.

- Rolled Product Quality Control: Apply rigorous quality control throughout the production of rolled products, ensuring they meet industry standards and specifications.

- Raw Materials and Spare Parts Quality: Conduct comprehensive quality checks on all raw materials and spare parts used in steel production, ensuring they meet the required standards for optimal production performance.